Transparent clarity, deep bass, and “Invisible Sound” from German audio company ADS. Background: One of the lesser known hi-fi brands of the ’70s, ADS (Analog and Digital Systems) […]

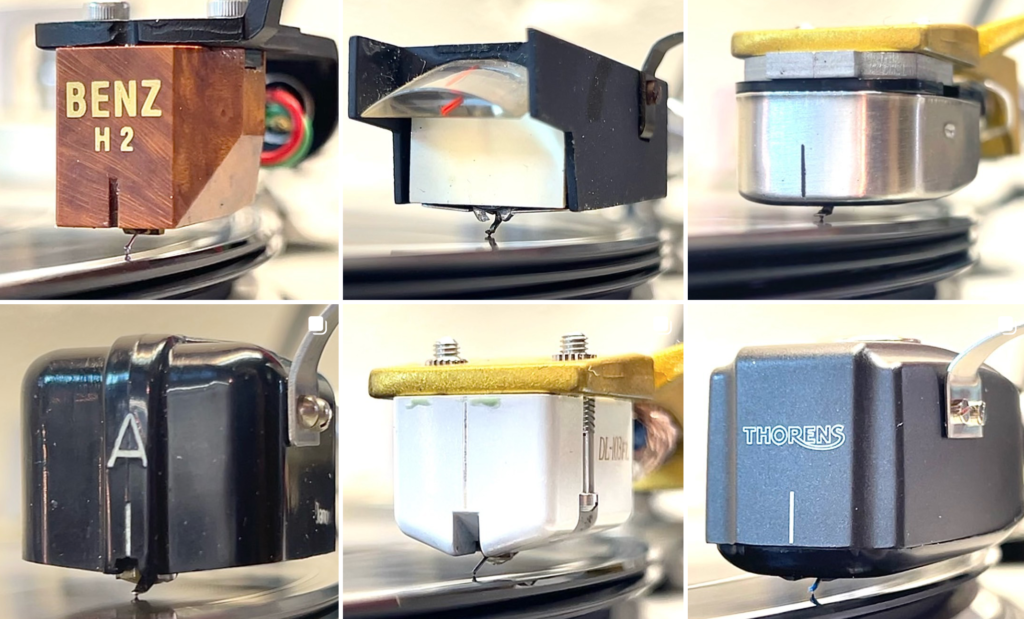

Turntable cartridges, Groovetickler and the beauty of micro-engineering

Full service retipping, diamond-only replacement, coil rewinds, suspension repairs from Joseph Long aka Groovetickler.

You likely know this, but the mechanical thing at the tip of your tonearm is as important as your turntable, amplifier or speakers when it comes to getting the most out of your music. About size of a Lego brick, that machine, called a cartridge, is the miraculous device that turns the sound waves inside a record groove into an electronic signal. The signal is then amplified and shot out of your speakers — as those reconstituted sound waves.

What you might not fully appreciate is the sheer bounty of cartridges built over the years, both by successful brands and by solo geniuses who understand the engineering and treat them as mini works of art. No one celebrates this world better than Joseph Long, aka Groovetickler, a self-described “High Fidelity Pickup Artist” who offers “full service retipping, diamond-only replacement, coil rewinds, suspension repairs.”

A cartridge mechanic who restores and rebuilds those loaded little magical boxes, Groovetickler documents his projects on Instagram, where he regularly uploads exquisitely photographed images like this one. (All photos are from Grooveticker’s Instagram.)

The description that Long provides next to the Sumiko cartridge above offers a glimpse of the cartridge universe:

Rare Sumiko SHŌ high output moving coil cartridge, once retipped by van den Hul. This now has a fresh new Fritz Gyger r/R 5/100 micron FG 2 diamond installed on the original boron cantilever for one of my earliest clients. This client started sending me cartridges way back when I was just experimenting when I was known on AudioKarma as “Needlestein,” and he gave me a lot of positive feedback, encouragement and confidence.

Long mentions a few different crucial components that make up a cartridge in that description. They’re defined below.

Fritz Gyger r/R 5/100 micron FG 2 diamond: That’s the stylus — the tiny pointed component that directly contacts the grooves. Like all styli, this Fritz Gyger reads the microscopic variations in the groove walls and translates them into vibrations.

Cantilever: a slender rod connecting the stylus (needle) to the internal generator system within the cartridge. The cantilever, a kind of mechanical bridge, transmits the movements of the stylus to the cartridge components.

Coil cartridge: There are two main types of internal generator systems, which are connected to the cantilever: moving magnet (MM) and moving coil (MC). The choice between MM and MC cartridges influences factors such cartridge weight and the overall sound profile. The SHŌ above features moving coils.

Last year, Long spoke with Resistor Magazine about cartridges and his work. Not only is it a fascinating conversation, but it’s a great primer on the wondrous device. It’s also a can of worms that will make you wonder whether you need to upgrade your own cartridge.

Asked by Resistor how people can ensure their cartridges enjoy a long life, Long replies:

Make sure the cleaning person knows to leave the turntable alone. After that, proper set up. I assess diamond wear whenever I get a cartridge to repair that still has a diamond. About half of them are unevenly worn which leads to premature failure. Avoid liquid cleaners of any kind. The idea that liquid cleaners travel up the cantilever and corrode the suspension and coils is not a myth. I’ve seen the damage. This is probably due to overuse, but still. I recommend dry Magic Eraser for cleaning.

In addition to these tips, one response by Long, a jack-of-all-trades mechanic who’s worked on much bigger machines, stuck with us. It was in response to a question on how he got started.

I had developed skills uniquely suited to cartridge or pickup repair. I had been challenging myself by repairing ever smaller things. Houses to cars to cameras to watches to pickups. There’s a lot of crossover there, too. I make all my own tools and some of them really are basically scaled down automotive tools with which I was familiar for doing similar jobs with cartridge repair. The way I get diamonds out of a cantilever without damage is the same way you get a ball joint out of a control arm. If you’re a mechanic, you know what I mean. The way I wind a coil is the same way you rewind an alternator – just on a miniature level.

Long is on eBay, fyi, where he’s a cartridge hunter-refurbisher who sells his wares.